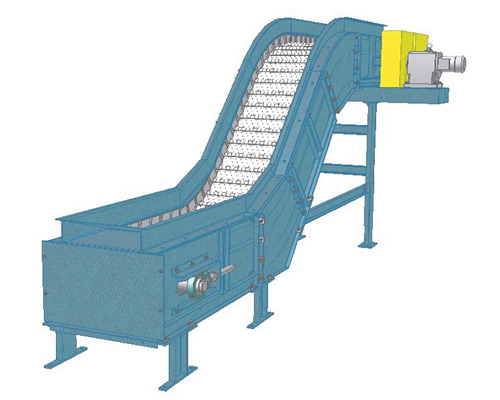

New London Engineering’s SteelTrak™ Hinged Steel Belt Conveyors are used to convey virtually any type of metal scrap. These rugged heavy-duty conveyors are designed to provide long-term low-maintenance operation handling metal scrap, steel chip, and fastener applications. They are ideally suited for conveying hot oily parts from punch presses, forging machines, etc. into steel drums or hoppers. Various apron, sidewing, siderail and frame designs are available. TruTrak flanged rollers built into the chain eliminate the side-to-side movement of the belt within the belt track. Because the belt cannot sway off it’s track, it can’t rub against the conveyor’s frame, virtually eliminating potential wear to the conveyor frame, the belt axles, sidewings, and cotter pins. TruTrak’s features also are the perfect choice in applications where prevention of downtime is a priority. A total of seven different models to choose from depending on the application. For specific information on each different model available, click on the following list of models below.

Model 715 equipped with 1-1/2″ pitch hinged steel chain, 4-1/2″ infeed (light duty)

Model 715 equipped with 1-1/2″ pitch hinged steel chain, 4-1/2″ infeed (light duty)

Models 720 & 723 equipped with 2-1/2″ pitch hinged chain, 8-1/2″ infeed (medium duty)

Models 720 & 723 equipped with 2-1/2″ pitch hinged chain, 8-1/2″ infeed (medium duty)

Models 721 & 724 with 2-1/2″ pitch hinged steel chain, 8-1/2″ infeed (standard duty)

Models 721 & 724 with 2-1/2″ pitch hinged steel chain, 8-1/2″ infeed (standard duty)

Models 722 & 726 equipped with 2-1/2″ pitch hinged steel chain, 6-5/8″ infeed (light duty)

Models 722 & 726 equipped with 2-1/2″ pitch hinged steel chain, 6-5/8″ infeed (light duty)

Model 725 equipped with 2-1/2″ pitch hinged steel chain, 5-3/8″ infeed (low profile)

Model 725 equipped with 2-1/2″ pitch hinged steel chain, 5-3/8″ infeed (low profile)

Model 727 equipped with 2-1/2″ pitch hinged steel chain, 6-5/8″ tapered infeed

Model 727 equipped with 2-1/2″ pitch hinged steel chain, 6-5/8″ tapered infeed

Models 750 & 751 equipped with 4″ pitch hinged steel chain, 15-1/4″ infeed

Models 750 & 751 equipped with 4″ pitch hinged steel chain, 15-1/4″ infeed

Model 760 equipped with 5″ pitch hinged steel chain, 21-3/4″ infeed

Model 760 equipped with 5″ pitch hinged steel chain, 21-3/4″ infeed

For more information on New London SteelTrak™ Hinged Steel Belt Conveyors, please call us at 1-877-355-1511 or complete the Request for Information form below.

REQUEST INFORMATION/QUOTE